Signalling and Telecom Works at Stockholm Central Station

Read the article

Expertises

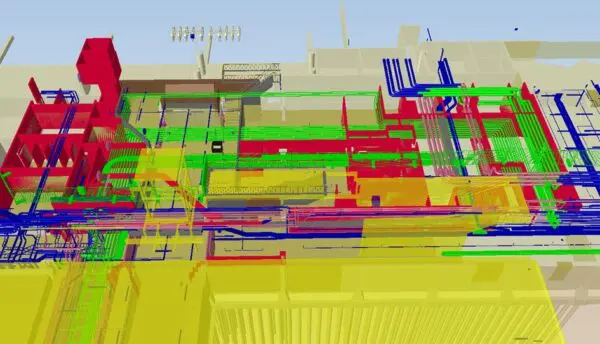

In complex, multidisciplinary projects, execution teams need clear insight into the design on site – down to the level of cables and pipelines. A powerful solution is Mixed Reality (MR), which projects the 3D design into the real-world environment on the construction site. This provides exactly the level of detail required.

The integrated design includes all disciplines. By linking the planning schedule, 4D visualisations make changes over time clearly visible, offering valuable insight.

In a standard 3D model, cables and pipelines are not individually visible. With Mixed Reality – via a headset (such as HoloLens) or a tablet – the construction team sees the design projected onto the actual environment, including cables and pipelines. This ensures the team knows exactly what to consider during execution.

Several design elements are exported from the BIM model and linked to printed markers or QR codes placed on site. These markers are precisely measured. Walking across the site, the user scans the markers with the HoloLens or tablet and instantly sees the correct design section overlaid on reality. The 3D design and the real-world environment merge seamlessly in view.

Positioning checks ensure accuracy, so users can trust the combination they see.

Mixed Reality supports Strukton’s strategy to use modern technology to manage complex, integrated projects. By combining the 3D BIM model with planning and real-world data, we ensure smooth execution and prevent errors and unsafe situations – minimising delays and failure costs.

During preparation, we capture as much reality as possible in the 3D model using 3D laser scanning, 360° imagery, and traditional measurements. During execution, we continue scanning – for example, after demolition – to keep the integrated model up to date.

The BIM model has proven its value in major design & construct projects such as:

This data-driven approach is managed by the BIM coordinator, who sets up the central cloud environment and ensures collaboration among all partners.

The value of the 3D model is significant. By integrating work preparation and planning into the design, we assess technical and scheduling feasibility. The model can also be used for:

Visualisations can show work areas, activities, and logistics to identify interfaces. Additional aspects such as waste flows, supply chains, and loading/unloading can also be included.

Sustainable station construction uses circular and recycled materials, optimised soil management and energy‑efficient construction methods. Rail organisations like Strukton also invest in low‑emission equipment, recycled contact wires, and sustainable construction logistics to reduce their carbon footprint. Many civil and rail contractors apply environmental management procedures to lower noise, emissions and waste during work in dense urban stations.

Advanced tools like BIM, 3D reality models, digital asset mapping and rail‑data systems support accurate planning, clash detection and risk reduction. These technologies allow teams to simulate construction stages, coordinate disciplines, and maintain rail operations more effectively. European rail organisations increasingly use digital models to ensure safe, sustainable and predictable delivery of infrastructure upgrades.

Station upgrades typically combine civil engineering, rail systems, structural works, cable and pipeline installation, telecom systems, travel‑information systems, platform construction, underpasses and bicycle parking. Integrating these disciplines under one coordinated framework reduces delays, prevents spatial conflicts and improves safety. Rail infrastructure specialists with Short Line, Rail‑Civil and engineering units routinely apply this integrated method in complex environments.

Working in a live station environment requires holistic and precisely synchronised planning. Multidisciplinary teams coordinate construction windows, material deliveries, rail possessions and stakeholder activities to minimise disruption to passengers and train services. This approach is used widely in complex rail environments across Europe, where rail contractors must maintain availability while executing renewal and upgrade works

Stations function as multimodal mobility hubs, where pedestrians, cyclists, buses, trams, taxis, trains and commercial activities converge. This density of movements requires careful planning, integrated construction phasing and coordination across many disciplines to maintain safety and accessibility. Station projects often involve platform reconstruction, track works, switches, overhead lines, underground structures, commercial areas and public‑space upgrades all at once

Asset management applies to rail infrastructure, roads, tunnels, waterways and all other civil structures where safety, availability and sustainability are essential. Whether managing complex rail networks or urban mobility systems, modern asset management frameworks—often supported by AI and predictive analytics—strengthen performance and ensure future‑proof infrastructure across Europe.

Data‑driven asset management provides an understanding of the condition and remaining lifespan of existing structures and assets. This insight enables infrastructure owners to plan renovations and renewals more efficiently, allocate investments wisely and reduce environmental impact by avoiding premature replacement. Advanced asset analytics help organisations make smart decisions and prioritise upgrades where they deliver the most value.