Emma Rotman

Manager Sustainability

Strukton

Date

07 April 2025

Expertise

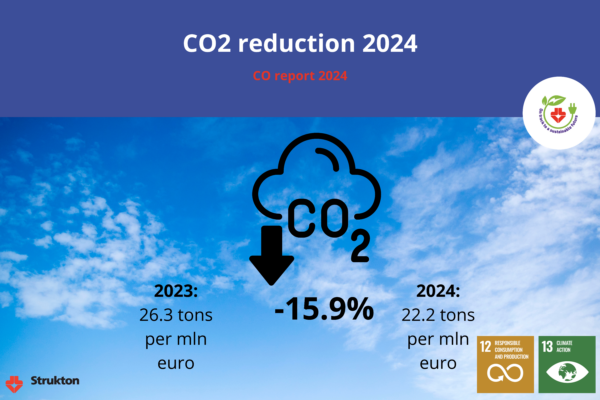

We are increasingly using electrical machines and equipment, on the one hand by retrofitting our own machines and equipment and on the other hand by hiring electrical machines and equipment. In dialogue with clients, suppliers and other industry peers, we work on feasible solutions for electrical energy supply on the construction site and the use of electrical machines.

Our initiatives and measures also aim to reduce scope 3 emissions. For example, we are working on catenary foundations and portals made of circular concrete, we reuse elements (switches, sleepers, pillars, transitions) and materials (circular concrete for platforms) and we are part of the sector-wide ‘Groene Liggers’ (Green Beams) initiative, which focuses on increasing the reuse ratio of beams.

A big thank you to everyone who contributes to the reduction, in the company and in the value chain. Reduction is something that should be done together! That is good for the earth and for the future.

Would you like to know more about our reduction, measures and initiatives? Read the report of 2024.

Manager Sustainability

Strukton

Sustainability in rail and civil engineering focuses on reducing environmental impact across the entire lifecycle of infrastructure. This includes using emission‑free equipment, circular and recycled materials, and designing assets with a longer lifespan and lower maintenance requirements. Reusing structural components—such as circular viaduct beams or recycled copper contact wires for overhead lines—significantly reduces CO₂ emissions while conserving valuable raw materials.

CO₂‑reduction is achieved through a combination of clean construction methods and material innovation. Key strategies include:

These measures not only reduce carbon emissions but help create more resilient, future‑proof infrastructure.

Infrastructure projects increasingly rely on advanced sustainable technologies, such as:

These innovations drive measurable environmental benefits throughout the asset lifecycle.

Zero‑emission equipment refers to machinery that operates without producing exhaust gases, typically powered by electricity or batteries. Examples include:

This equipment eliminates local emissions, improves air quality around work sites, reduces noise pollution and helps clients comply with increasingly strict sustainability requirements.

By 2050, the infrastructure sector aims to be fully climate‑neutral. This future includes:

The transition is already underway, driven by innovation, collaboration and long‑term thinking.