Strukton expands Belgian rail activities

Read the article

Working in the ground? Planning excavation work? First check what’s below the surface. In the subsurface, there is always a chance that cables or pipelines are present that are not shown on existing maps. Striking a cable or pipeline can cause serious damage to underground infrastructure, resulting in high additional costs, delays and inconvenience for local residents. Fortunately, this is preventable. Before starting any work, scan the project area with our 3D ground‑penetrating radar and gain insight into the subsurface conditions.

We mount our ground radar beneath an electric quad or hand‑pushed cart, allowing us to map the underground environment in a sustainable way. For our own work in railway environments, we also mount the system on the Leonardo Inspection Train.

Below are several practical applications of the 3D ground‑penetrating radar.

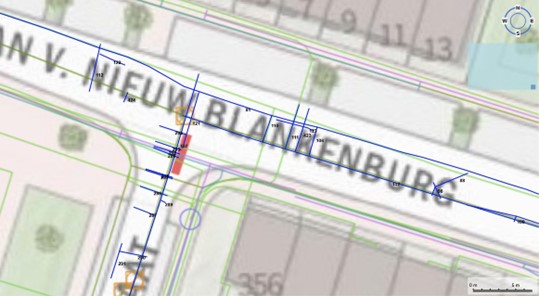

Verify known positional data and record the precise location of cables and pipelines, including their actual depth (cover verification). Unknown cables or pipelines are often found as well. Ground radar research can significantly reduce the number of trial trenches required.

Example of radar data interpretation (blue) on a KLIC background.

During project planning and execution, Building Information Models (BIM) are often used to create and manage spatial information. However, underground data is frequently missing.

With 3D radar, you gain an additional subsurface dimension in the model, optimising project planning and execution (e.g. clash detection, determining available space, etc.).

We can also provide above‑ground 3D scans. If desired, all available data — both current and future conditions — can be visualised using AR applications or processed into a digital twin.

Voids can cause subsidence and structural damage to roads, dykes and other assets. Ground radar makes it possible to detect early‑stage voids, such as those caused by washouts or animal activity (badgers, beavers, water voles, etc.), as well as cracking due to damage or drought.

Example of a detected fox den.

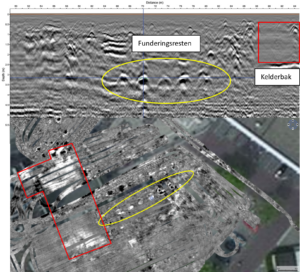

The subsurface often contains remnants of historical structures (foundation remains, piles, basement structures, underground tanks, etc.). In some cases, these may have archaeological value. With 3D radar, an area can be scanned comprehensively for underground objects or obstacles.

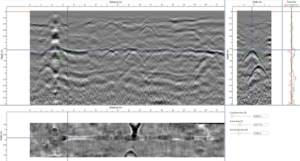

Example of a full‑coverage radar scan of an undeveloped site showing subsurface obstacles. A = depth profile in scan direction, B = top‑down depth slice at approx. 3 m below ground level.

Ground radar enables us to “scan through” civil structures and assess their condition. This includes identifying concrete layer thickness, reinforcement grids, prestressing, corrosion of reinforcement, cracking, delamination and moisture ingress.

Example of a radar scan of a bridge deck showing the surface layer, concrete layer with reinforcement and approach slabs.

Ground radar can be used to determine the layer structure of soil and pavement. It allows accurate, full‑coverage mapping of asphalt thickness and the underlying foundation layers. This results in more precise estimates of material volumes.

In addition, ground radar can detect cracking, delamination and washouts. A further advantage is that it simultaneously provides insight into the subsurface beneath the pavement layer (manholes, cables/pipelines, voids, etc.).

Asset management applies to rail infrastructure, roads, tunnels, waterways and all other civil structures where safety, availability and sustainability are essential. Whether managing complex rail networks or urban mobility systems, modern asset management frameworks—often supported by AI and predictive analytics—strengthen performance and ensure future‑proof infrastructure across Europe.

Data‑driven asset management provides an understanding of the condition and remaining lifespan of existing structures and assets. This insight enables infrastructure owners to plan renovations and renewals more efficiently, allocate investments wisely and reduce environmental impact by avoiding premature replacement. Advanced asset analytics help organisations make smart decisions and prioritise upgrades where they deliver the most value.

Predictive maintenance helps prevent unexpected failures, avoids costly emergency repairs and keeps infrastructure available at the lowest operational impact. By identifying deviations at an early stage, repairs can be scheduled during planned maintenance windows—often at night—reducing disruptions and improving asset performance. Studies show predictive models significantly reduce unplanned outages and improve safety across transport networks.

Data is the foundation of smart maintenance. By collecting condition data from inspections, sensors and monitoring systems, infrastructure managers gain accurate insight into the health of their assets. When combined with analytics, software and AI, this data enables predictive maintenance frameworks that reduce downtime, improve reliability and support informed, long‑term decision‑making.

Sustainable asset management balances performance, cost efficiency and environmental impact across the entire lifecycle of infrastructure. It focuses on extending asset life, minimising failures and reducing CO₂ emissions through smarter maintenance planning and responsible material use. Modern approaches increasingly integrate predictive maintenance and sustainability goals to improve long‑term resilience. The POSS monitoring system and Eurailscout’s inspection trains are examples that boost sustainable asset management.

Rail construction plays a crucial role in Europe’s shift towards low‑carbon mobility. By expanding and modernising electric rail infrastructure, the sector enables cleaner transport that produces significantly lower CO₂ emissions than road or air travel. At the same time, energy‑efficient work methods—such as using low‑emission machinery, hybrid traction systems and digital tools that extend asset life—help reduce the environmental footprint of construction activities. Together, these developments strengthen a sustainable mobility network and accelerate progress towards European climate goals.

In rail construction, highly specialised machinery ensures that work is carried out safely, efficiently and with minimal disruption. Typical equipment includes track‑laying trains, tamping machines, rail welding units, road‑rail excavators and ballast profiling systems, each designed to build or restore track structures with precision. These machines support both large‑scale track installation and daily maintenance operations. Innovations in automation and robotics are increasingly enhancing productivity and safety, helping infrastructure managers deliver consistent quality in a growing European rail network.